t

The economical alternative

Laser Cladding instead of HVOF

up to 50% cost advantage!

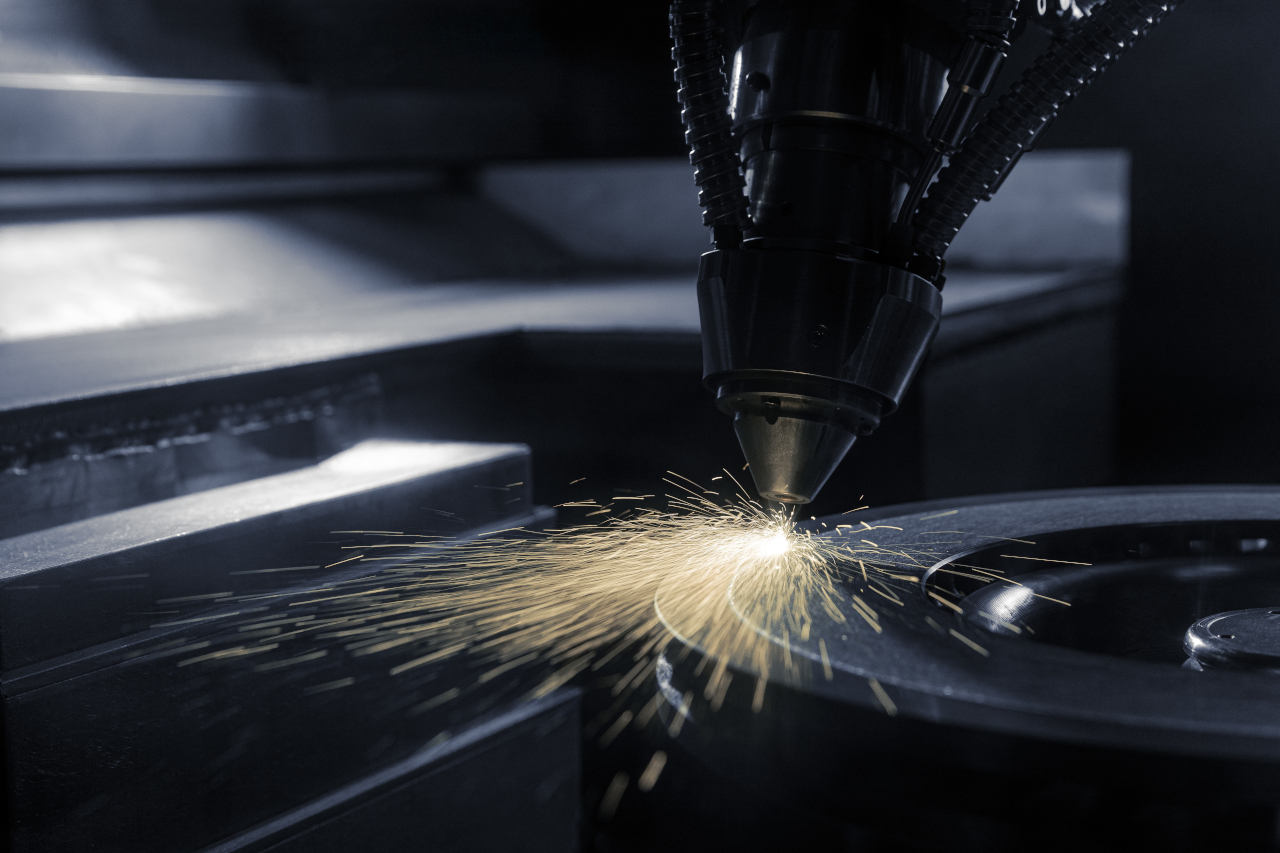

Laser Cladding: the economical alternative to thermal spraying / HVOF

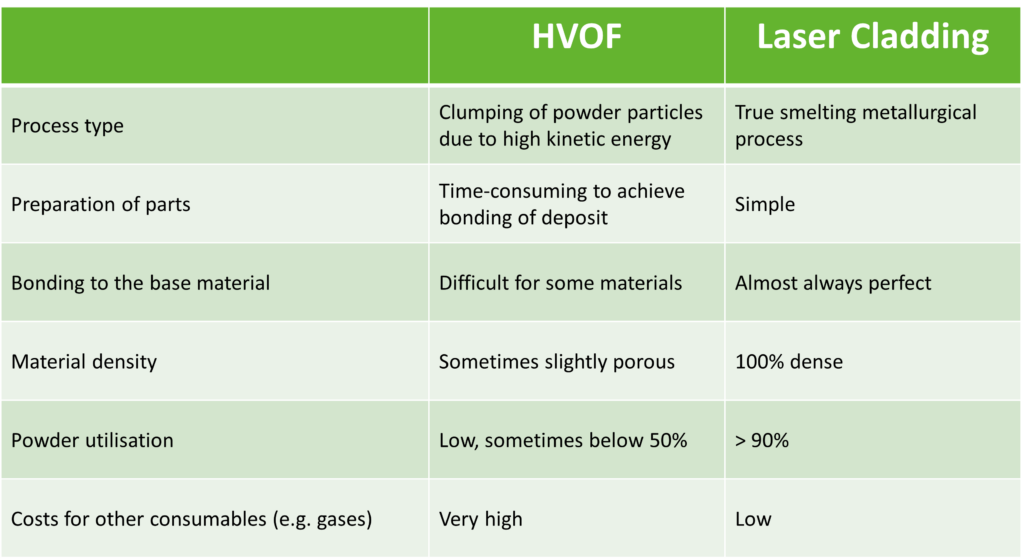

HVOF (High Velocity Oxygen Fuel) is a thermal spray process that has proven itself in the production of high-quality functional coatings. However, it is associated with high costs, which is why alternative processes are increasingly being used. Laser cladding is a superior alternative because it offers decisive advantages.

Advantages of laser cladding compared to HVOF

Laser cladding offers unbeatable advantages over thermal spray processes, especially HVOF:

These advantages mean that coatings produced using laser cladding are up to 50% cheaper than comparable coatings produced using HVOF.

Other laser cladding/laser cladding/DED applications

Coating

- Substitution hard chromium plating

- Substitution thermal spray

- Substitution conventional laser deposition

- So far uncoated components

Additives Manufacturing

- Highly flexible production of geometric elements on semi-finished products, e.g. sealing lips or flanges (hybrid additive production)

- Functional integration

- In-situ combination processes (e.g. turning & AM)

Repair

- Repair of components that could not be repaired up to now due to the high heat input

- Mobile repair systems for conventional machine tools

Examples of possible materials

Matrix materials and corrosion protection

- Nickel alloys: NiCr, NiCrMo, NiCrBSi, …

- Iron alloys: 304L, 316L, 430L, 17-4-Ph, M2, …

- Cobalt alloys: CoCr, CoCrMo, CoCrW, CoCrW, …

- Others: titanium-, aluminium-, copper-, …

Hard phases/carbides

- Tungsten carbide

- Titanium carbide

- Chromium carbide

- Silicon carbide

- Molybdenum carbide

- …

Material content up to 60% by volume depending on combination

Contact us!

Your contact person for applications:

Dr.-Ing. Phillip Utsch

+49 241 6083 230

t