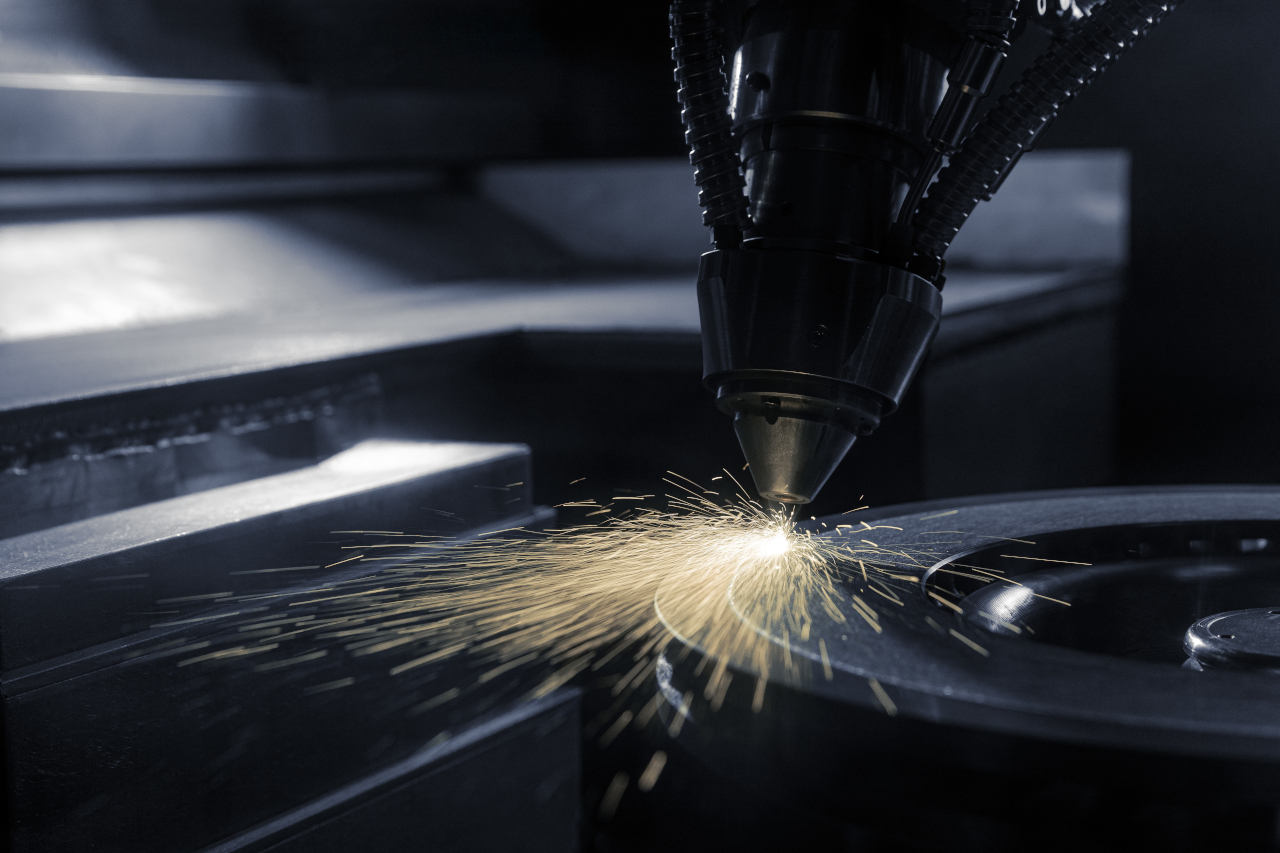

Laser Cladding

for Plain Bearings

Materials for plain bearings produced with laser cladding: highest quality and productivity

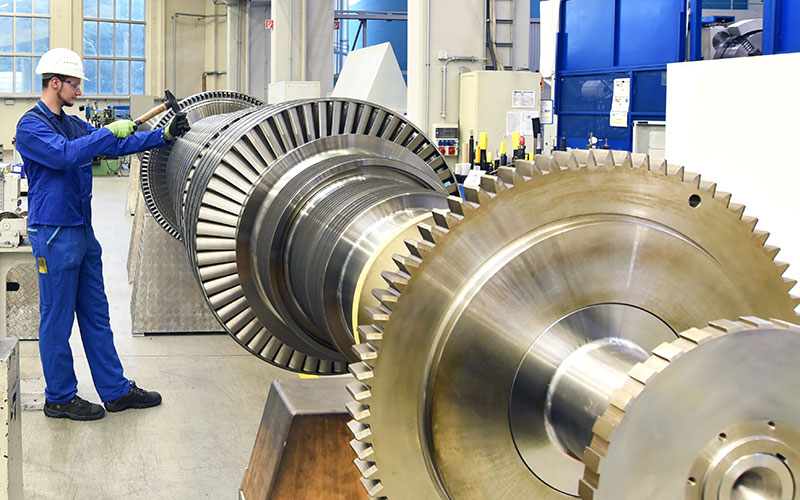

Plain bearings are required for a wide variety of applications. Gearboxes for wind turbines are currently an outstanding application. Due to the ever-increasing performance of wind turbines and the geometric restrictions imposed on them, hydrodynamic plain bearings are increasingly being used in the planetary gearboxes of wind turbines. HPL Laser Cladding provides the desired plain bearing materials in unrivaled quality with the exact layer thickness required. This is done so precisely that subsequent processing steps can be minimized.

However, plain bearing layers produced with laser cladding can also be used in other industries. For example, they can be found in marine or automotive applications. Different materials are used, such as bronze alloys or white metal.

Total solutions for plain bearings

HPL offers complete solutions for plain bearing coating that go far beyond the machine. Our application center is equipped with an impressive portfolio of lasers of various types up to 22 kW and offers the opportunity to carry out process and application developments for your application. We work with you to determine the most suitable machine concept and support you with our process expertise right up to the start of production. As a contract service provider, we can also cover your production peaks or provide support during the ramp-up phase.

Other laser cladding/laser cladding/DED applications

Coating

- Substitution hard chromium plating

- Substitution thermal spray

- Substitution conventional laser deposition

- So far uncoated components

Additives Manufacturing

- Highly flexible production of geometric elements on semi-finished products, e.g. sealing lips or flanges (hybrid additive production)

- Functional integration

- In-situ combination processes (e.g. turning & AM)

Repair

- Repair of components that could not be repaired up to now due to the high heat input

- Mobile repair systems for conventional machine tools

Examples of possible materials

Matrix materials and corrosion protection

- Nickel alloys: NiCr, NiCrMo, NiCrBSi, …

- Iron alloys: 304L, 316L, 430L, 17-4-Ph, M2, …

- Cobalt alloys: CoCr, CoCrMo, CoCrW, CoCrW, …

- Others: titanium-, aluminium-, copper-, …

Hard phases/carbides

- Tungsten carbide

- Titanium carbide

- Chromium carbide

- Silicon carbide

- Molybdenum carbide

- …

Material content up to 60% by volume depending on combination

Contact us!

Your contact person for applications:

Dr.-Ing. Phillip Utsch

t