t

Robust production solitions

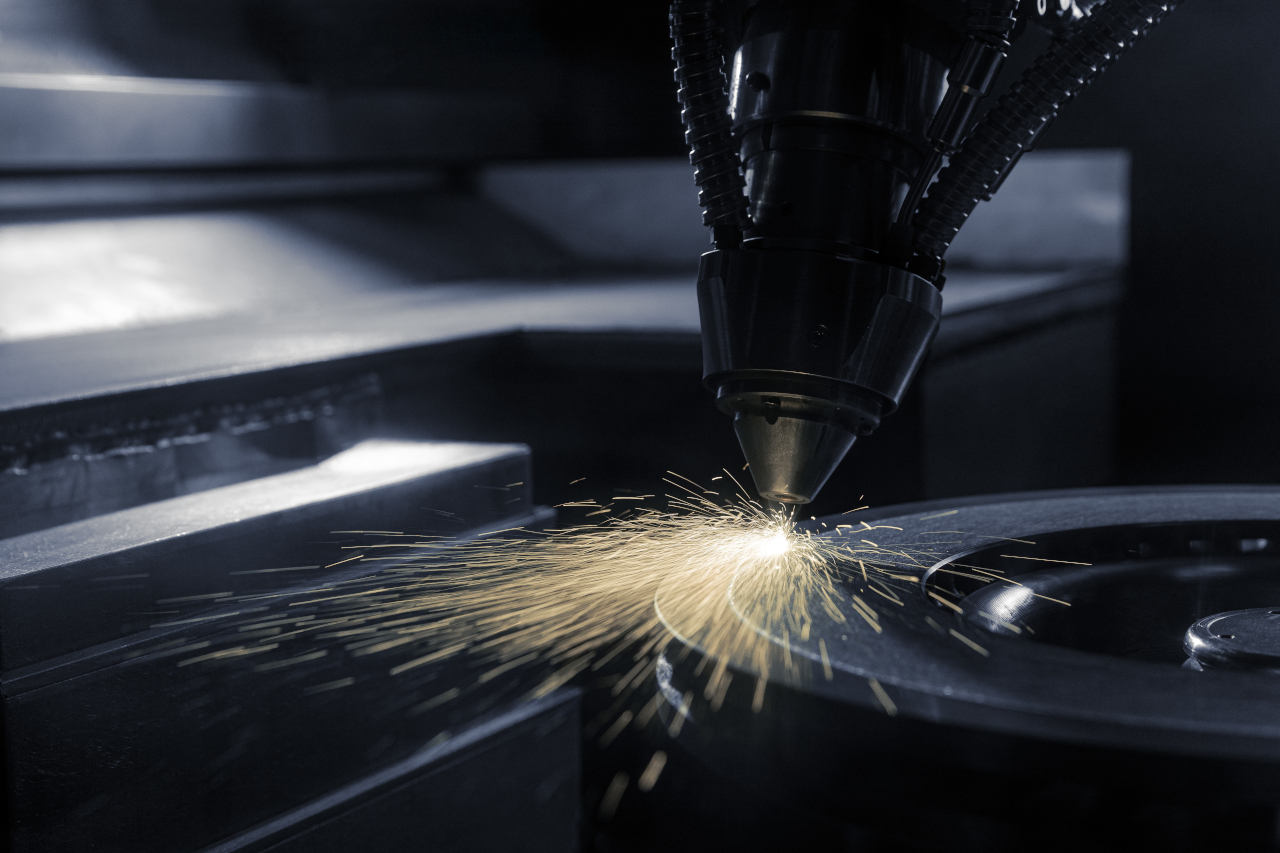

Laser Cladding

for Steel Production

Laser cladding/laser coating: wear protection for rollers and other components in steel production

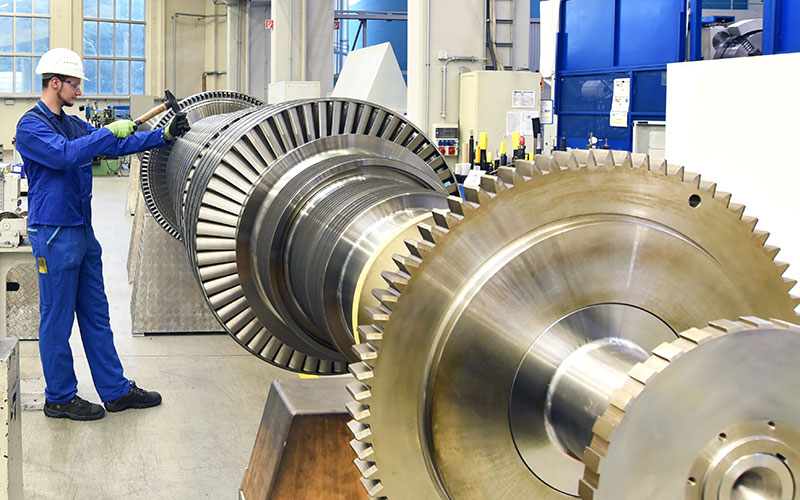

The steel industry places very special requirements on the production systems used. Round-the-clock operation, high temperatures and wear-prone processes are just some of the challenges. With laser cladding solutions from HPL Technologies, components such as rollers, drills, conveyor elements or cutting blades can be provided with coatings that can withstand harshest environments. In this way, service lives can be significantly improved and the productivity of the manufacturing process can be considerably increased.

Customized solutions

HPL offers the steel industry customized laser cladding solutions from a single source. In addition to laser cladding machines, the product portfolio also includes feasibility studies, the development of material and coating systems and application developments. In addition, job shop coating services are offered for small series as well as for large production volumes.

A variety of coating materials are available. These can be iron-, nickel-, cobalt- or carbide-based, for example. We provide customized coating systems for every application, using both conventional and high-speed laser cladding. The components to be coated can be of almost any size; both small tools and rollers weighing several tons can be processed without any problems thanks to the modular concept of our technology.

Other laser cladding/laser cladding/DED applications

Coating

- Substitution hard chromium plating

- Substitution thermal spray

- Substitution conventional laser deposition

- So far uncoated components

Additives Manufacturing

- Highly flexible production of geometric elements on semi-finished products, e.g. sealing lips or flanges (hybrid additive production)

- Functional integration

- In-situ combination processes (e.g. turning & AM)

Repair

- Repair of components that could not be repaired up to now due to the high heat input

- Mobile repair systems for conventional machine tools

Examples of possible materials

Matrix materials and corrosion protection

- Nickel alloys: NiCr, NiCrMo, NiCrBSi, …

- Iron alloys: 304L, 316L, 430L, 17-4-Ph, M2, …

- Cobalt alloys: CoCr, CoCrMo, CoCrW, CoCrW, …

- Others: titanium-, aluminium-, copper-, …

Hard phases/carbides

- Tungsten carbide

- Titanium carbide

- Chromium carbide

- Silicon carbide

- Molybdenum carbide

- …

Material content up to 60% by volume depending on combination

Contact us!

Your contact person for applications:

Dr.-Ing. Phillip Utsch

t