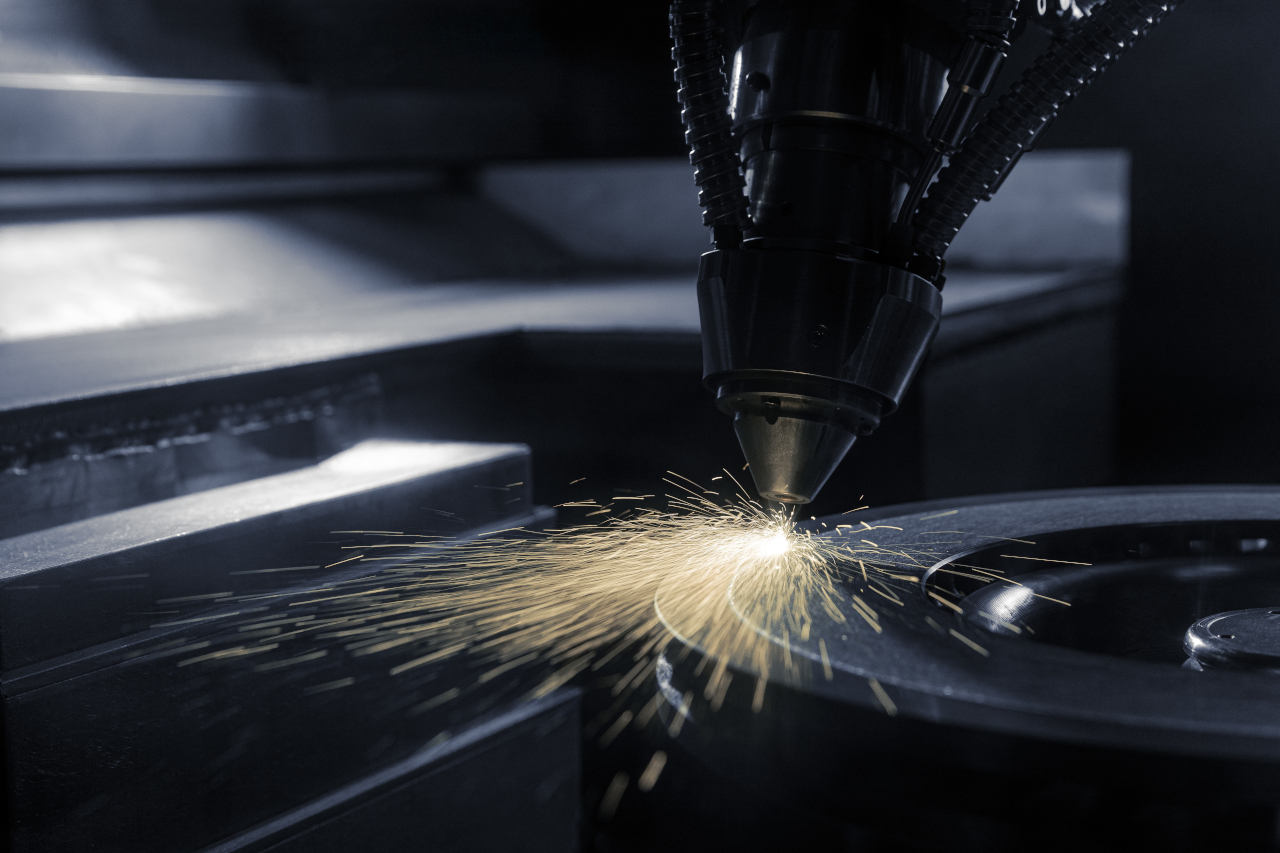

Laser Coating

Applications

The innovative HPL laser coating technology offers unique advantages for a variety of applications. A wide range of industries benefit from unique added values. HPL Technologies offers comprehensive complete solutions - from feasibility studies and application development to turnkey machines and job shop services.

Fields of application and industries

Other laser cladding/laser cladding/DED applications

Coating

- Substitution hard chrome plating

- Substitution of Thermal Spray processes

- Substitution conventional LA

- PTA coatings

- So far uncoated components

Additives Manufacturing

- Highly flexible production of geometric elements on semi-finished products, e.g. sealing lips or flanges (hybrid additive production)

- Functional integration

- In-situ combination processes (e.g. turning & AM)

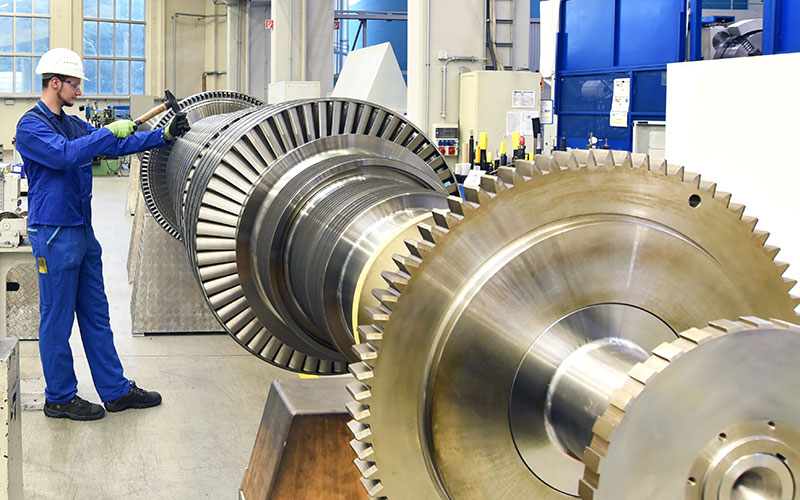

Repair

- Repair of components that could not be repaired up to now due to the high heat input

- Mobile repair systems for conventional machine tools

Examples of possible materials

Matrix materials and corrosion protection

- Nickel alloys: NiCr, NiCrMo, NiCrBSi, …

- Iron alloys: 304L, 316L, 430L, 17-4-Ph, M2, …

- Cobalt alloys: CoCr, CoCrMo, CoCrW, CoCrW, …

- Others: titanium-, aluminium-, copper-, …

Hard phases/carbides

- Tungsten carbide

- Titanium carbide

- Chromium carbide

- Silicon carbide

- Molybdenum carbide

- …

Material content up to 60% by volume depending on combination

Contact us!

Your contact person for technology:

Dr.-Ing. Phillip Utsch

+49 241 6083 230